Posts

Showing posts from July, 2012

Posted by

Derek Olson (Oldwolf)

A Little Band Saw Love

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

Spicy Stopped Dados By Hand

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

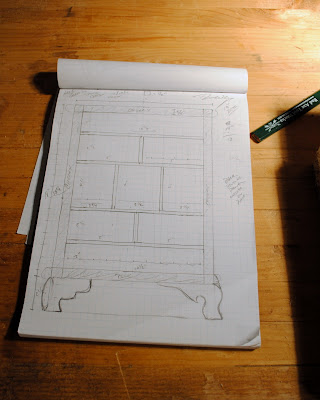

A Start To A Spice Chest

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

A Good Weekend For A Comeback

- Get link

- Other Apps