Posts

Showing posts from June, 2010

Posted by

Derek Olson (Oldwolf)

Escape to the Bat Cave Boy Wonder!!

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

Methods of Work: Mortise and Tenon Joints

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

The Drawbore Oddessy

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

I'm Not Shaping the Wood, I am Beginning to Shape Myself.

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

Doweling Plate

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

Looming Deadlines

- Get link

- Other Apps

Posted by

Derek Olson (Oldwolf)

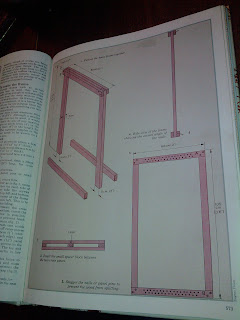

And Lo, There Stood a Loom.

- Get link

- Other Apps